Guaranteed nitrogen purity at the lowest energy cost

You can purchase Nitrogen Generators PSA Technology from GDK with confidence, as we are a proficient producer of high-quality Nitrogen Generators PSA Technology. We promise to provide you with the best after-sale service and prompt delivery.

Our state-of-the-art PSA generator lets you produce your own, reliable supply of nitrogen with a purity of up to 99.999% and up to 40% savings in energy.

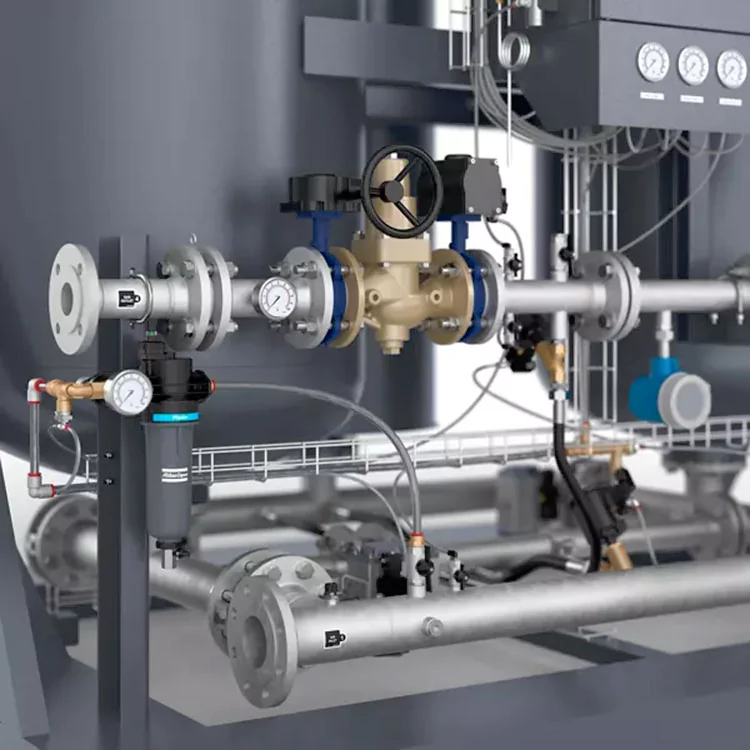

When your production requires high-quality, high-flow nitrogen, there is no better solution than the Atlas Copco NGP⁺450-2800. To ensure the integrity and continuity of your production, the NGP⁺monitors the quality of your feed air and your gas output 24/7. Choose the NGP⁺’s superior efficiency to give you an industry-leading combination of peace of mind and the lowest cost of ownership.

Food and beverage

Packaging: Nitrogen gas can be used to displace oxygen in food packaging, which helps to preserve the quality and freshness of the product. This is particularly important for products such as coffee, nuts, and snack foods, which are sensitive to oxidation.

Modified Atmosphere Packaging (MAP): Modified atmosphere is the practice of modifying the composition of the internal atmosphere of a package to improve the shelf life. This is commonly used in food or drug packaging. The modification process often tries to lower the amount of oxygen (O2), moving it from 20.9% to 0%, to slow down the growth of aerobic organisms and the speed of oxidation reactions that might take place in food and beverage products.

Dispensing: Nitrogen gas can be used to dispense beer and other carbonated beverages, which helps to create a foamy head and a smooth, creamy texture. This is because nitrogen gas is less soluble than carbon dioxide, which creates smaller bubbles and a smoother mouthfeel.

Processing: Nitrogen gas can be used in food processing applications to help prevent oxidation and microbial growth. For example, it can be used to create an oxygen-free environment during the processing of oils and fats, which helps to prevent rancidity.

Pharmaceutical

Blanketing: Creating an oxygen-free environment in pharmaceutical manufacturing and packaging processes is important for maintaining the quality and purity of the products,

particularly those that are sensitive to oxidation.

Purging: Nitrogen Purging equipment and pipelines of air, moisture, and other contaminants is important for preventing contamination of the product and maintaining the sterility of the manufacturing environment.

Spray drying: Nitrogen gas is often used in the spray drying process, which is used to produce powdered formulations of pharmaceutical products. The nitrogen gas is used to create a lowhumidity environment, which helps to prevent the powder from clumping or caking.

Oil & gas and chemicals

Inerting tanks for explosion prevention: Inerting is the process of replacing the air inside a tank or vessel nitrogen to prevent explosions or fires.

Fire prevention: Nitrogen is the gas of choice to displace oxygen and prevent explosions. It is mainly used to flush piping system and blanketing of stored explosive or flammable products.

The result is safety, reliability and protection from corruption through oxidation.

Pressure testing: Nitrogen is an inert gas, meaning it will not react with the materials used in the equipment or pipeline. Nitrogen can also be used to purge equipment of other gases that may be present, such as oxygen or flammable gases.

Gas lifting: This process is known as gas lifting, and it involves injecting nitrogen into the wellbore to create pressure that helps move the oil to the surface.

Well stimulation: Nitrogen is pumped into the wellbore and creates pressure that fractures the rock, allowing oil and gas to flow more easily.

Corrosion prevention: By displacing oxygen and other corrosive gases, nitrogen can help protect the metal surfaces from degradation.

Sealing of gas compressors: Nitrogen is often used as a sealing gas in compressors to prevent leakage and ensure the efficient operation of the equipment.

Overall, nitrogen is a versatile gas that plays an important role in the oil and gas industry. Its inert properties and ability to create pressure make it a valuable tool for various applications in the industry.

Steel

Purging: Nitrogen is used to purge oxygen and other gases from furnaces and other equipment used in the steelmaking process. This helps to prevent oxidation of the steel and ensures a highquality end product.

Blanketing: Nitrogen is used to create an inert atmosphere in furnaces and other equipment to prevent oxidation of the steel during processing.

Cooling: Nitrogen is used as a cooling agent in the steelmaking process. It is often used in combination with water to cool hot steel and prevent warping or other damage.

Cutting: Nitrogen is used as an assist gas in plasma cutting and laser cutting of steel. The highpressure nitrogen stream helps to blow away molten metal and other debris from the cut, resulting in a clean, precise cut.

Annealing: Nitrogen is used as a shielding gas during the annealing process, which is used to improve the properties of steel. The nitrogen creates an inert atmosphere around the steel, preventing oxidation and ensuring a high-quality end product.

Electronics

Soldering and wave soldering: Nitrogen gas is used to create an inert atmosphere around the soldering process, preventing oxidation of the metal components and ensuring high-quality solder joints.

Reflow soldering: In this process, Nitrogen gas is used to reduce the presence of oxygen, which can cause oxidation of the solder and reduce the quality of the connection.

Cleaning: Nitrogen gas is used to remove contaminants from electronic components during the manufacturing process. It is also used to blow away dust and debris from sensitive electronic equipment.

Testing: Nitrogen gas is used in the testing of electronic components and devices, particularly those that are sensitive to oxygen or moisture. It can be used to create a controlled atmosphere for testing or to purge the device of oxygen or other contaminants.

Storage: Nitrogen gas is also used to store electronic components and devices. By replacing the air with nitrogen, oxidation and other forms of degradation can be prevented, ensuring the longevity and reliability of the components.

Whether your company is specialized in chemical manufacturing, electronics, laser cutting or food and beverage, a dependable supply of industrial gas is crucial.

Compared to the on-demand delivery of gas bottles or tanks, on-site production of gas offers a wealth of advantages ranging from cost savings to continuous availability.

Atlas Copco’s advanced nitrogen generators offer you the ultimate solution: flexible on-site production of nitrogen at the lowest possible cost.

On-site vs. liquid or bottled gas Your own independent supply of nitrogen.

Non-stop availability: 24 hours a day, 7 days a week.

Significant economies of scale and lower operation costs: no rental charges, transport expenses and bulk user evaporation losses.

No safety hazards when handling high-pressure cylinders.

Easy integration within existing compressed air installations.

High reliability

Proven technology: simple, reliable and durable. The exact purity your application demands. Low operating costs for extra cost-efficiency. World-class expertise in a unique market offer from compressed air to gas.

New generation PSA generators will change the market Atlas Copco’s latest PSA generators extend the advantages of the current range. Total lifecycle cost consists of the initial investment cost of the on-site installation, the service cost, and the energy cost. The NGP range has the lowest investment cost. However, with increasing running time, you are better advised to switch to the NGP+ range to reduce energy costs.

Total lifecycle cost

With an air factor* of 1.8 (at 95%) to 5.5 (at 99.999%) and a special cycle time modulation algorithm, the running cost of the new NGP+ can be reduced by 50%, compared to other N2 generators.

The air factor is calculated by dividing the inlet air your system needs by the amount of N2 it produces. The lower the air factor, the more efficient your nitrogen generation.

The complete high-flow nitrogen generator

In this chapter discover features of the NGP and their benefits

Electronics

Advanced Elektronikon® Touch controller with large HD color touchscreen offers easy gas purity selection, purity alarm, feed air monitoring and interception, and connectivity options.

Automatic start-up and stand-by mode allow for easy operation and avoid energy waste.

Application protection system ensures only gas that meets the minimum purity requirement will reach your application.

The generator and its software are designed to utilize the premium Carbon Molecular Sieve adsorbent with maximum Efficiency.

Valves

The valves of a PSA generator switch every minute on average.

Because of their intensive use, these valves play an important role in the reliable operation of the generator and the continuity of your production. That is why the NGP⁺ features in-house qualified, heavy-duty valves with a long service life.

Sensor

Digital zirconia gas purity sensor, flow meter, and pressure regulator included as standard.

Highest quality adsorbent/CMS

• High density due to packed bed technology.

• Top/bottom equalization.

• Protected by dedicated pressure sensor.

• Low air consumption.

Self-protective monitoring of the feed air quality

• Temperature.

• Pressure.

• Pressure dewpoint.

• Automatic feed air blow-off in case of contamination.

Automatic start-up

• Minimum pressure valve with bypass nozzle for fast start-up.

• Eliminates risk of overflow and CMS damage.

PSA reliable and proven

Based on Pressure Swing Adsorption (PSA) technology, Atlas Copco’s NGP/NGP+ nitrogen generators provide a continuous flow of nitrogen at desired purity.

High purity nitrogen supply up to 99.999%

Atlas Copco’s NGP/NGP+ nitrogen generators use Pressure Swing Adsorption technology to isolate nitrogen molecules from other molecules in compressed air. Oxygen, CO2, water vapor and other gases are adsorbed. The result is virtually pure nitrogen at the outlet of the generator. The.

NGP/NGP+

Series is a very cost-efficient source of nitroge nused in various industries like food and beverage, metal processing, electronics, and many others.

Variable cycle saver

Most users don’t utilize the maximum capacity of their nitrogen generator all the time.

Our in-house developed Variable Cycle Saver (VCS) eliminates energy waste during lower demand and in colder temperatures, giving you up to 40% additional energy savings.

1. Low load: When there is less demand for nitrogen, VCS optimizes the PSA cycle to reduce the generator capacity and thus the feed air consumption to what is needed to generate the lower volume.

2. Full load: The generator is sized for reliable production at full load in hot temperatures (if applicable). In these conditions, VCS is not needed.

3. Seasonal efficiency: At full load in cold conditions, a nitrogen generator works more efficiently, increasing its capacity. Here, the VCS of the NGP⁺ will also kick in to reduce feed air and energy costs.

|

Type |

|

Nitrogen capacity |

Dimensions (W x D x H) |

Weight |

||||||||||||

|

95% |

96% |

97% |

98% |

99% |

99.50% |

99.90% |

99.95% |

99.99% |

99.995% |

99.999% |

mm |

in |

kg |

lbs |

||

|

NGP 450+ |

Nm³/h |

970 |

876 |

787 |

680 |

557 |

471 |

337 |

258 |

197 |

176 |

127 |

2703 x2100 x3028 |

106x83x119 |

5687 |

12538 |

|

Scfm |

571 |

304 |

400 |

324 |

272 |

198 |

152 |

116 |

104 |

75 |

||||||

|

NGP 550+ |

Nm³/h |

1187 |

1073 |

963 |

833 |

682 |

577 |

412 |

315 |

242 |

216 |

155 |

2780 x2100 x3022 |

107x83x119 |

6403 |

14116 |

|

Scfm |

699 |

632 |

567 |

490 |

401 |

340 |

242 |

185 |

142 |

127 |

91 |

|||||

|

NGP 650+ |

Nm³/h |

1421 |

1284 |

1152 |

997 |

816 |

690 |

493 |

377 |

289 |

258 |

186 |

2880 x2100 x3025 |

113x83x119 |

7360 |

16226 |

|

Scfm |

836 |

756 |

678 |

587 |

480 |

406 |

290 |

222 |

170 |

152 |

109 |

|||||

|

NGP 800+ |

Nm³/h |

1780 |

1608 |

1444 |

1249 |

1023 |

865 |

618 |

473 |

362 |

323 |

232 |

3684 x3121 x3987 |

145x123x157 |

8755 |

19301 |

|

Scfm |

1048 |

946 |

850 |

735 |

509 |

278 |

213 |

190 |

137 |

|||||||

|

NGP 1000+ |

Nm³/h |

2258 |

2040 |

1831 |

1584 |

1298 |

1097 |

784 |

600 |

459 |

410 |

295 |

3773 x3121 x4211 |

149x123x166 |

10619 |

23411 |

|

Scfm |

1329 |

1201 |

1078 |

932 |

764 |

646 |

461 |

353 |

270 |

241 |

174 |

|||||

|

NGP 1300+ |

Nm³/h |

2871 |

2594 |

2329 |

2014 |

1650 |

1395 |

996 |

762 |

584 |

521 |

375 |

3860 x3122 x4423 |

152x123x174 |

12368 |

27267 |

|

Scfm |

1690 |

1527 |

1371 |

1185 |

971 |

821 |

586 |

449 |

344 |

307 |

221 |

|||||

|

NGP 1600+ |

Nm³/h |

3352 |

3029 |

2719 |

2352 |

1927 |

1628 |

1164 |

890 |

681 |

608 |

437 |

4430 x3365 x4892 |

174x132x193 |

16750 |

36927 |

|

Scfm |

1944 |

1757 |

1577 |

1364 |

1117 |

944 |

675 |

515 |

394 |

352 |

253 |

|||||

|

NGP 2000+ |

Nm³/h |

3993 |

3608 |

3239 |

2801 |

2295 |

1940 |

1386 |

1060 |

811 |

724 |

521 |

4480 x3515 x5036 |

176x138x198 |

18750 |

41337 |

|

Scfm |

2316 |

2092 |

1878 |

1625 |

1331 |

1125 |

804 |

613 |

470 |

419 |

301 |

|||||

|

NGP 2400+ |

Nm³/h |

4787 |

4325 |

3882 |

3358 |

2751 |

2325 |

1661 |

1271 |

973 |

868 |

624 |

4600 x3520 x5200 |

181x139x205 |

2500 |

5512 |

|

Scfm |

2776 |

2508 |

2251 |

1948 |

1595 |

1348 |

963 |

735 |

563 |

502 |

361 |

|||||

|

NGP 2800+ |

Nm³/h |

5791 |

5233 |

4697 |

4063 |

3328 |

2813 |

2010 |

1537 |

1177 |

1050 |

756 |

4770 x3990 x5116 |

188x157x201 |

30750 |

67792 |

|

Scfm |

3358 |

3035 |

2724 |

2356 |

1930 |

1631 |

1166 |

890 |

681 |

608 |

437 |

|||||

Address

Room 2021, Building 5, Lane 1215, Yushu Road, Yongfeng Street, Songjiang District, Shanghai, China

Tel